Toyota - Automotive Industry

Toyota Ecuador is the regional distributor and service provider for Toyota vehicles, coordinating with Toyota International to ensure world-class quality in sales, after-sales, and spare parts management.

The company operates across multiple locations and serves thousands of customers, requiring agile, secure, and reliable technology systems to manage inventory, logistics, and customer service.

The Challenge:

Modernizing a Critical, 20-Year-Old System

Toyota Ecuador’s 20-year-old inventory and operations management system had reached its limits.

- •Outdated architecture with shared dependencies that slowed system evolution.

- •Limited web-only access, preventing staff from using data in the field.

- •Lack of integration between Toyota Ecuador’s internal processes and Toyota International’s requirements.

- •Inefficient spare parts storage and location tracking.

Designing Coexistence Without Disruption

Aligning Local and Global Needs

Redefining the Architecture

- Implemented an Identity and Access Management (IAM) service, giving Toyota granular control over permissions and security across all applications.

- Set up continuous integration and deployment (CI/CD) flows to ensure quality control and rapid availability of updates and new features.

- Split application components:

- Backend (Python + Flask): Business logic, data management.

- Client Applications (Web & Mobile): Field operations, dashboards, and reporting for purchase, sales, and inventory changes.

Enabling Versatility and Growth

Field-First Operations

Key Features Implemented

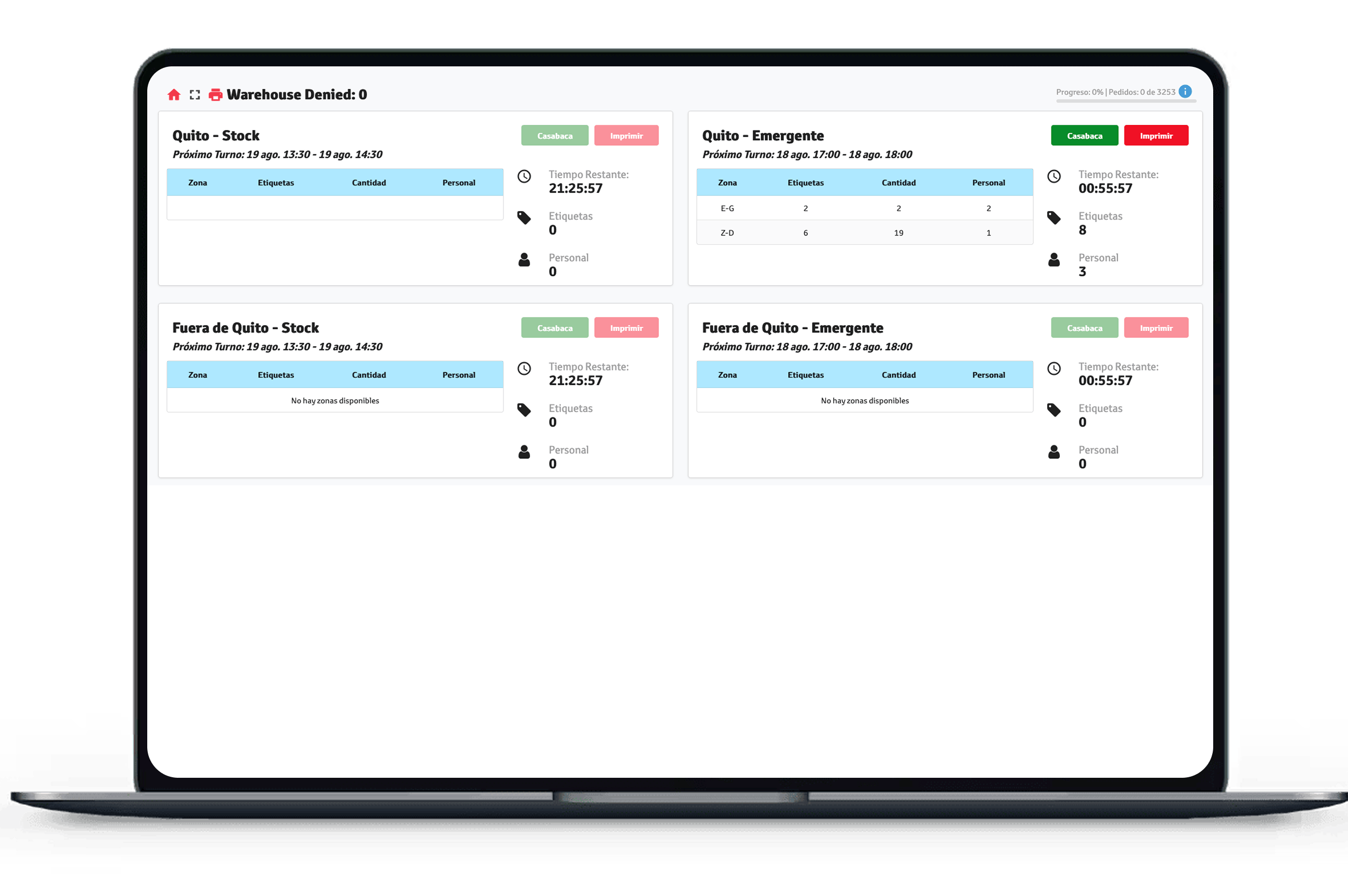

Warehouse Location Management

Faulty Part Detection

Real-Time Data Access

Cross-Application IAM Integration

The Impact

- 40% faster spare parts preparation and delivery due to optimized storage strategies.

- Reduced operational downtime during system transition thanks to coexistence planning.

- Improved standing: In 2019, Toyota Japan recognized TEMS as a management benchmark in the region.

- Future-ready architecture, enabling expansion into vehicle tracking and logistics management.

The Results: Measurable Business Impact

Financial Advancements

Operational Gains

Service Reliability

Voices from Toyota

"TEMS enables decision-making precision we never had before."

"The platform has mastered inventory management in ways that directly impact our service excellence."

FAQs

The primary goal was to replace Toyota Ecuador’s 20-year-old inventory system with a modern, real-time platform that integrated both local and international requirements, optimized operations, and enabled field access without disrupting ongoing work.

We designed both systems to coexist during the transition, maintaining data consistency while gradually replacing old features with new ones. This allowed users to adapt to TEMS step-by-step without downtime.

The solution was built with a Python + Flask backend, web and mobile applications for field operations, Identity and Access Management (IAM) services, and continuous integration and deployment (CI/CD) pipelines for faster updates.

We introduced warehouse location management, categorizing spare parts by size and function. This reduced search and preparation time by 40% and improved faulty parts detection for returns and warranties.

Yes. In 2019, Toyota Japan recognized TEMS as a management benchmark in the region for its operational efficiency and adaptability.